| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Supply Ability : | 800 tons per day |

| Price : | To be negotiated |

| Brand Name : | Xinyue Steel |

| Model Number : | Anti Corrosion Steel Pipe |

| Certification : | ce, JIS, ISO9001 |

| Payment Terms : | L/C, T/T |

| Delivery Time : | 7 - 15 days |

| Product Name | Anti-Corrosion Steel Pipe |

| Usage | Long distance water transportation, petroleum and gas transmission and chemical industry |

| Standard | API 5L PSL1/ PSL2 , ASTM A252, EN10219, AWWA C200, ASTM A53, BS, JIS, etc... |

| ASTM A 53 | Gr. A, Gr B, Gr C, Gr.D |

| API 5L | A, B, X42, X46, X52, X56, X60, X65 X70 |

| GB/T9711 | L175, L210, L245, L290, L320, L360, L290, L320, L360, L390, L415, L450, L485, L555 |

| ASTM A252 | Gr.1 Gr.2 Gr.3 |

| EN 10219 | S235JR, S275JR, S355JR, S355JOH, S355J2, S420... |

| Outer Diamter | 219.1mm - 4064mm (8" - 160") |

| Wall Thickness | 4 mm - 25.4mm |

| Length | Up to 96m |

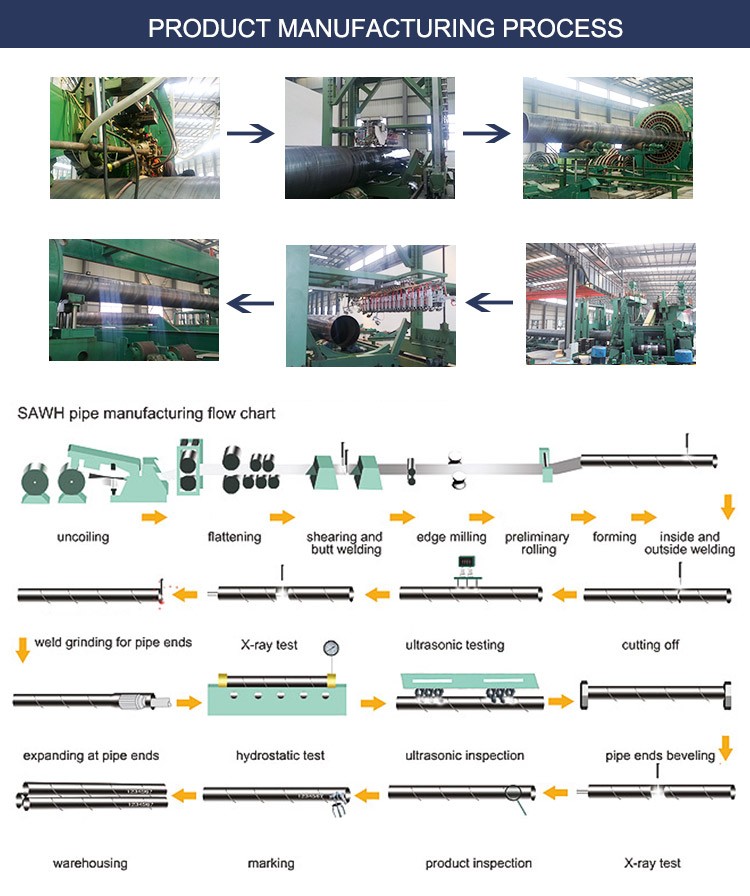

Spiral Steel Pipe is made by rolling low-carbon carbon structural

steel or low-alloy structural steel strip according to a certain

spiral angle (called forming angle) into a tube blank, and then

welding the tube seam together. It can be made with a narrower

Strip steel produces large diameter steel pipes. Its specifications

are expressed by outer diameter * wall thickness, and the welded

pipe shall be ensured that the hydraulic test, the tensile strength

of the weld and the cold bending performance must meet the

requirements.

Advantages of spiral welded pipe:

(1) Steel pipes of different diameters can be produced using strip steel of the same width, and

steel pipes of large diameter can be produced from narrow strip steel.

(2) Under the same pressure conditions, the stress of the

spiral welded seam is smaller than that of the straight seam, which is 75% to 90% of that of the straight seam welded pipe, so it can withstand greater pressure. Compared with the straight seam welded pipe of the same outer diameter, the wall thickness can be reduced by 10% to 25% under the same pressure.

(3) The size is accurate, the general diameter tolerance does not exceed 0.12%, the deflection is less than 1/2000, and the ovality is less than 1%. Generally, the sizing and straightening process can be omitted.

(4) Continuous production is possible. In theory, long steel pipes can be produced, with small head and tail loss, and can

increase the metal utilization rate by 6% to 8%.

(5) The equipment is light in weight and low initial investment. It can be made into a trailer-type mobile unit to directly produce welded pipes at the construction site where the pipeline is laid.

Q: What kind of surface treatment can you offer?

A: We can offer Anti-rust coating, bitumen coating, FBE, 2PE, 3LPE,

Polyamide Epoxy, Rich Zinc Primer, Polyurethane, etc.

Q: How much is MOQ?

A:For the goods in stock ,1 ton is okay. For customized and special

material orders,20 tons for each size.

Q: Do you provide other steel pipes?

A: Xinyue's main products include ERW, LSAW, SSAW, SMLS,

Scaffolding, SHS and RHS, Couplers and pipe fitting. And we provide

carbon steel, alloy steel, and stainless steel products.

Q: What is your main market for SSAW steel pipe?

A:Main market for SSAW steel pipe includes Middle East, South

Africa, Southeast Asia, Australian and Latin America.

Q: Is it OK to print customer’s logo on steel pipe product?

A: Yes. please inform us formally before our production and confirm

the design.

|